The Role of Weather in Fashion Manufacturing: Insights from Phnom Penh

Fa

Understanding the Impact of Weather on Fashion Manufacturing

Fashion manufacturing is a complex industry influenced by various factors, and one of the often-overlooked elements is the weather. In Phnom Penh, Cambodia, a city known for its burgeoning fashion manufacturing sector, understanding how weather impacts production processes is crucial. From materials to logistics, weather plays a significant role in shaping the efficiency and output of fashion manufacturing units.

Phnom Penh experiences a tropical climate with distinct wet and dry seasons. This climate variability can have profound effects on the manufacturing timeline and the quality of the finished products. Manufacturers must strategize to mitigate any negative impacts caused by these seasonal changes, ensuring consistent quality and timely delivery.

Material Selection and Sourcing

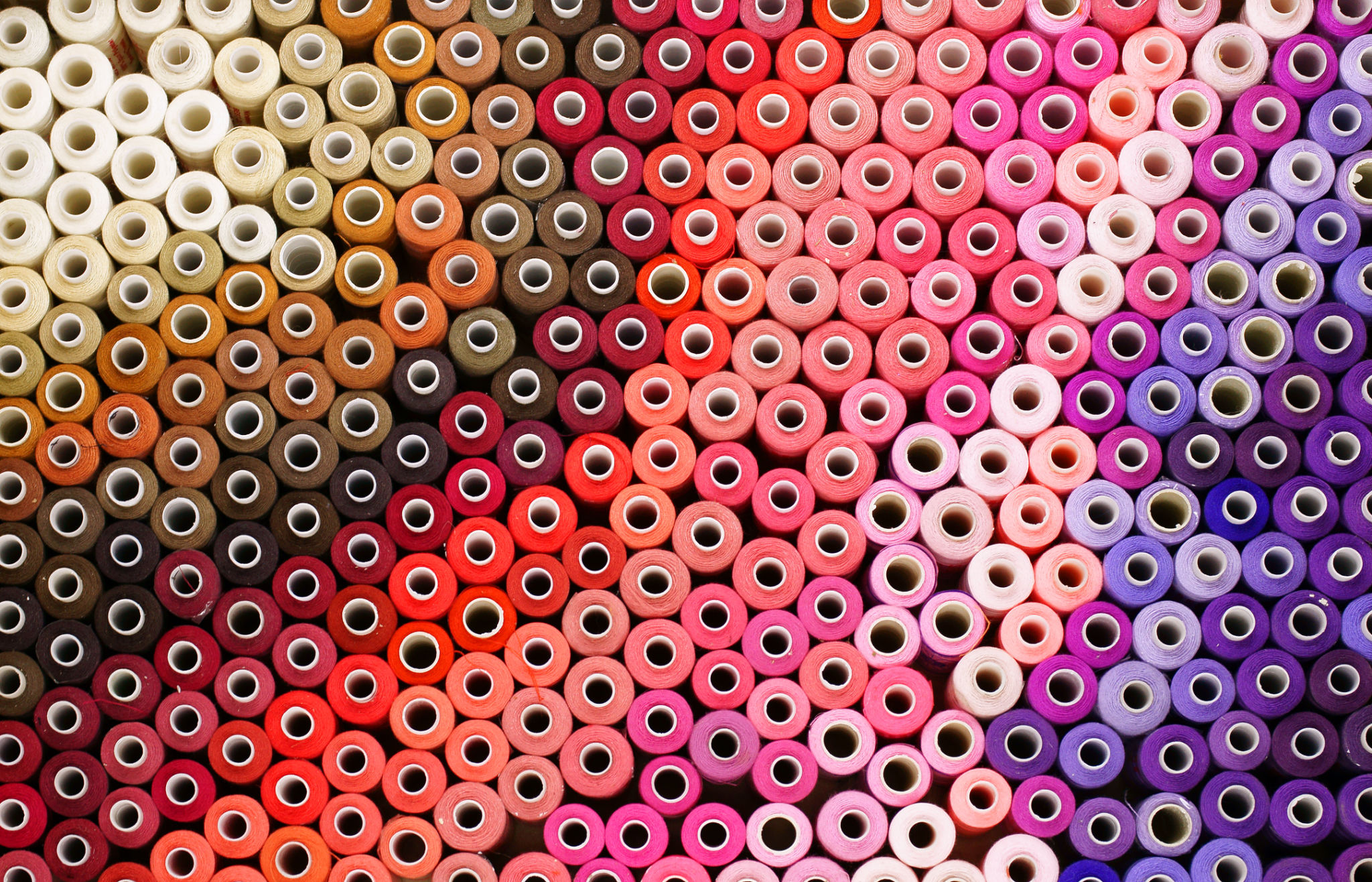

The choice of materials in fashion manufacturing is heavily influenced by the weather. In humid conditions, which are prevalent during Phnom Penh's wet season, some fabrics may become prone to mold or damage. Manufacturers often prefer synthetic materials or treat natural fabrics with protective coatings to withstand moisture.

Moreover, sourcing materials can become challenging during adverse weather conditions. Transportation delays due to flooded roads or disrupted supply chains during heavy rains can lead to shortages in material availability, affecting production schedules.

Production Process Adjustments

The production process itself must adapt to the changing weather patterns. During the dry season, the heat can accelerate certain processes like dye setting but may also pose challenges such as increased energy costs for cooling systems. Conversely, high humidity levels during the wet season can slow down processes like drying and curing, necessitating adjustments in workflow and timelines.

To combat these challenges, many manufacturers invest in climate-controlled facilities that maintain consistent temperature and humidity levels. This not only ensures a steady production pace but also helps in maintaining the quality of the garments produced.

Quality Control and Assurance

Weather conditions can directly impact the quality of fashion products. High humidity may lead to fabric shrinkage, color fading, or print smudging. Thus, rigorous quality control measures are essential to ensure that the finished products meet international standards.

Implementing advanced quality assurance techniques and regular inspections during various production stages helps in identifying potential issues early. Manufacturers often employ technology such as automated quality control systems to minimize human error and enhance precision.

Logistics and Distribution Challenges

The weather also affects logistics and distribution aspects of fashion manufacturing. During the monsoon season, transportation can be severely disrupted, leading to delays in shipping finished products to global markets. Manufacturers in Phnom Penh need robust contingency plans to handle such disruptions effectively.

Strategies for Weather Adaptation

To minimize the impact of adverse weather, manufacturers may implement various strategies such as building resilient infrastructure, investing in advanced forecasting technologies, and maintaining flexible production schedules. These measures enable them to adapt quickly to unexpected weather changes and maintain smooth operations.

In conclusion, while Phnom Penh's fashion manufacturing industry faces significant challenges due to weather conditions, proactive strategies and adaptive techniques can help mitigate these impacts. By understanding and anticipating weather-related issues, manufacturers can ensure that they remain competitive and continue to thrive in the global market.